Copyright © Zhangjiagang Feihang Technology Co., Ltd. All Rights Reserved. Site Map

- 0086-512-58454577

+86-18662225300 - sales@feihang.com

- No. 9, Qinghai Road East, Yangtze River International Chemical Industry Park, Jiangsu Province

According to FutureMarketInsights, Inc., the global green and bio-based polyol market is in a rapid growth phase.

The market is expected to reach $35.6 billion (about 267.6 billion RMB) by 2035, with an average annual growth rate of 10.3%. In addition, from 2025 to 2035, the market is expected to grow at a compound annual growth rate (CAGR) of 11.7%.

Why is bio-based polyol growing so fast? What "magic" does it have to attract so much investment?

01

What is bio-based polyol?

Polyol is an organic polymer, a large class of alcohols containing two or more hydroxyl groups in the molecule. Traditional polyether polyols are restricted by petroleum resources and are unsustainable products.

Bio-based polyols are a class of polyol compounds obtained by chemical or biochemical methods using renewable biomass as raw materials. According to the source of raw materials and chemical structure, they can be divided into plant oil-based polyols (soybean oil, castor oil, palm oil, etc. as raw materials), sugar-based polyols (glucose, fructose, sucrose, etc. as raw materials), cellulose-based polyols (cellulose, lignin, etc. as raw materials) and other biomass-based polyols (starch, protein, etc. as raw materials).

02

What are the technical routes?

Direct conversion of sugar raw materials: Xunyuan Technology adopts a unique technical route to directly convert sugar into polyols, omitting the traditional step of producing ethanol through sugar fermentation. This method simplifies the production process, reduces production steps, and provides greater flexibility for production companies.

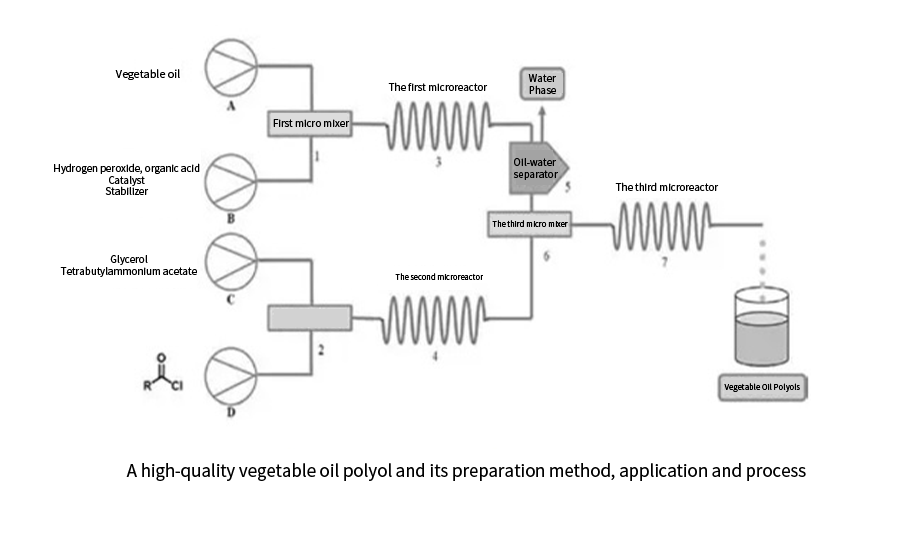

Plant oil-based polyol synthesis method: Using plant oils (such as rapeseed oil, soybean oil, etc.) as raw materials, bio-based polyols are prepared by epoxidation, hydroxylation and other methods. For example, soybean oil polyols are prepared by ring-opening reaction of epoxidized soybean oil and ethylene glycol, or bio-based polyols are prepared by transesterification of fatty acid dimers.

Lignin-based polyol synthesis method: Using lignin as raw material, it is converted into bio-based polyols through chemical modification methods. This method is suitable for areas with rich lignin resources and can be produced continuously, avoiding the problem of competing with food crops for resources.

Microalgae oil-based polyol synthesis method: Using microalgae oil as raw material, bio-based polyols are prepared by epoxidation-ring opening method and hydroformylation-hydrogenation reduction method. This method has high raw material utilization rate and environmental protection.

Waste utilization method: Some research teams have developed methods for extracting bio-based polyols from plant waste (such as beet pulp, tomatoes, peppers, etc.), which not only improves resource utilization, but also reduces environmental pollution.

Among these technical routes, glycosylation technology is considered to be one of the most commonly used and potential technical routes because it directly utilizes sugar raw materials and omits intermediate steps, simplifying the production process.

03

What is the market layout of bio-based polyols?

From the perspective of the market structure, in recent years, the global bio-based polyol production enterprises are mainly foreign leading enterprises, such as BASF, Dow, DuPont, SK Chemicals, Cargill, Mitsui Chemicals, Emery Oleochemicals, Huntsman, etc. The top ten enterprises in the world account for nearly 60% of the market, with a high degree of concentration.

Specific layout of some enterprises:

In August 2024, Cargill Bioindustry passed the USDA BioPreferred™ certification. Its high-performance Priplast™ polyester polyol is 100% bio-based, covering two types of amorphous and semi-crystalline, and has a wide range of molecular weights (from 1000 to 3000). The product can adapt to different application scenarios and customer needs.

In July 2023, Wanhua Chemical applied for a patent called "A method for synthesizing bio-based polyols". This technology can significantly increase the bio-based content of polymer polyols without affecting the performance of polymer polyols.

In May 2022, BASF put into operation the first bio-based polyol production line in the Asia-Pacific region in Mangalore, India, to meet the demand for environmentally friendly products in the fields of new energy vehicles, wind power, flooring and industrial coatings in the Asia-Pacific region, giving the first bio-based polyol production line in the Asia-Pacific region a market first-mover advantage.

In March 2023, Beijing Xunyuan Technology Co., Ltd. used sugar as raw material to directly convert sugar into polyols, omitting the traditional process of producing ethanol by fermentation of sugar.

In November 2021, SK Chemical established a mass production system with a scale of thousands of tons, operating special facilities to produce new bio-polyol materials with special mass production facilities, and continued to expand its business in the field of biomaterials.

04

What are the market applications?

At present, in terms of application, bio-based polyols are mostly used in polyurethane, bio-based nylon, adhesives, coatings, consumer electronics, automobiles, textiles and clothing, and other fields, and downstream applications are very extensive.

The following is an inventory of some of the current applications of bio-based polyols:

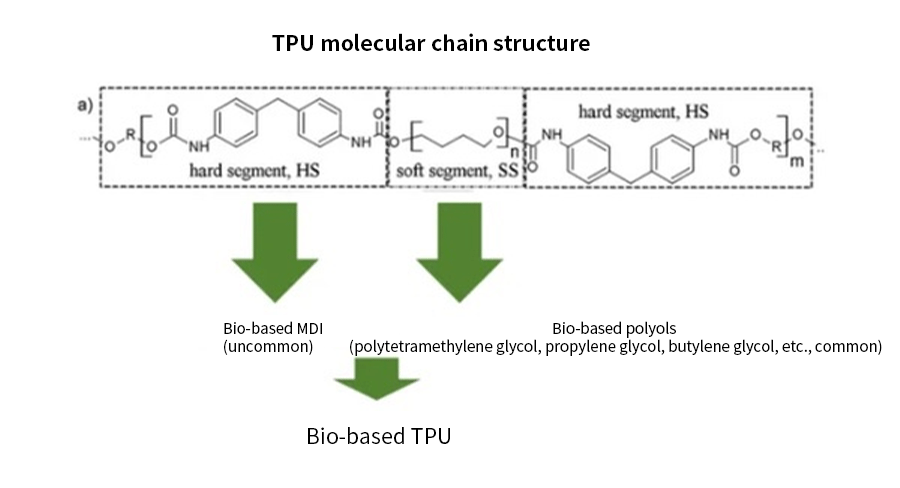

Polyurethane industry: Bio-based polyols are key ingredients in polyurethane production and are widely used in foams, coatings, adhesives and elastomers. For example, soybean oil polyols are widely used in automobile manufacturing and packaging materials due to their biodegradability and good water resistance.

In addition, bio-based polyols are also used to produce high-performance polyester materials such as polytrimethylene terephthalate (PTT), which can be used in textile fibers and engineering plastics.

Coatings and adhesives: Bio-based polyols replace petroleum-based polyols in coating production, providing an environmentally friendly alternative. These polyols not only help develop environmentally friendly products, but also meet the coatings industry's demand for high-performance materials.

New energy and automobile manufacturing: Bio-based polyols are also used in new energy vehicles and wind power, such as as part of battery materials and insulation materials.

Other applications: Bio-based polyols are also used to produce products such as adhesives, sealants and elastomers, which have high requirements for environmental protection and sustainability.

05

Difficulties and challenges

Despite the broad market prospects, the green and bio-based polyol industry also faces some challenges:

High production costs: The manufacturing process is complex and the cost of raw materials is higher than that of traditional petroleum-based products, resulting in higher prices for the final products and lack of competitiveness in price-sensitive markets.

Supply chain constraints: The supply of sustainable raw materials, such as vegetable oils and sugars, can be unstable and vulnerable to factors such as climate change, changes in crop yields, or geopolitical issues.

Scaling and technology constraints: Many green polyol production technologies are still in the development or pilot stage, and scaling up production to meet industrial needs while maintaining cost-effectiveness and sustainability is a major challenge.

Performance and compatibility: Bio-based polyols may not perform as well as traditional products in some aspects, such as poor durability or mechanical properties. Ensuring that they meet the same standards as traditional polyols is critical for market promotion.

Regulatory and certification challenges: The green and bio-based polyol industry faces a complex regulatory environment, with different standards in different regions around the world. Obtaining certification for the "green" or "bio-based" label can be time-consuming and costly, hindering market growth and promotion.

06

Summary

Although the green and bio-based polyol market faces challenges such as high production costs, unstable supply chains, limited technology scalability, performance and certification, the market is still growing significantly as demand for sustainable materials increases, especially in polyurethanes, coatings, new energy and other fields.

To meet these challenges, companies still need to continue to invest in research and development to create opportunities for bio-based polyols to replace traditional petroleum-based products.